1. Connect to the vehicle in Forscan.

2. Click the Oscilloscope button in the left column

3. Click the small gear button at the bottom of the window.

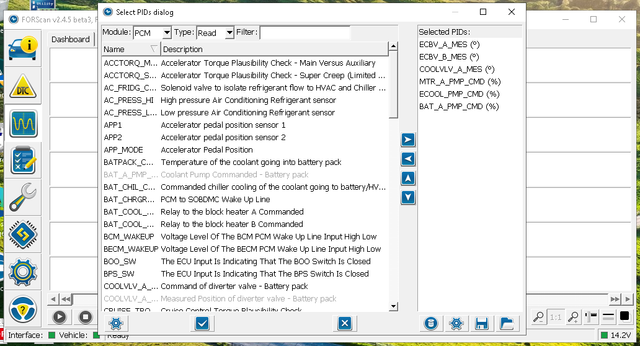

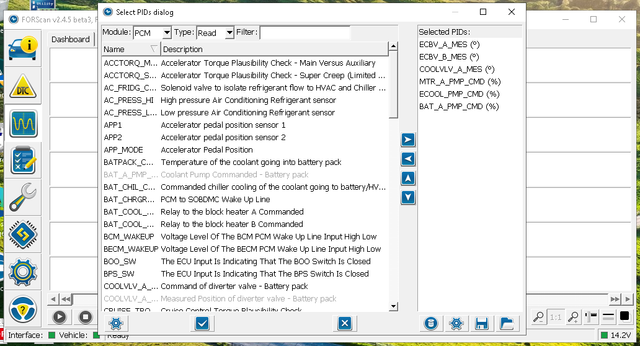

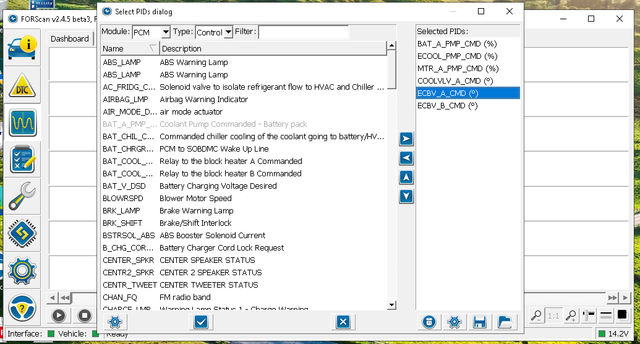

4. Select PCM from the Module drop down.

5. Select the PIDs as seen in the photo.

6. Click the check mark button at the bottom of the window.

7. Click the small gear button at the bottom of the window.

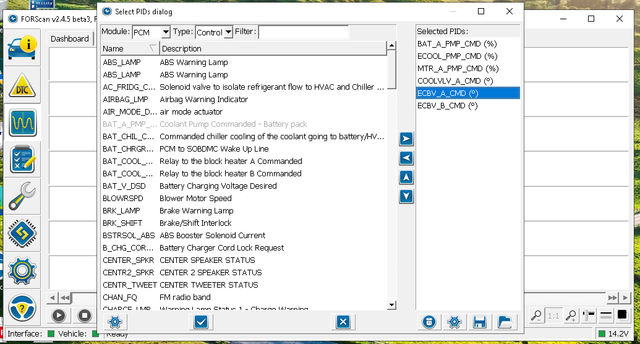

8. Select PCM from the Module drop down.

9. Select Control from the Type drop down.

10. Select the PIDs as seen in the photo.

11. Click the check mark button at the bottom of the window.

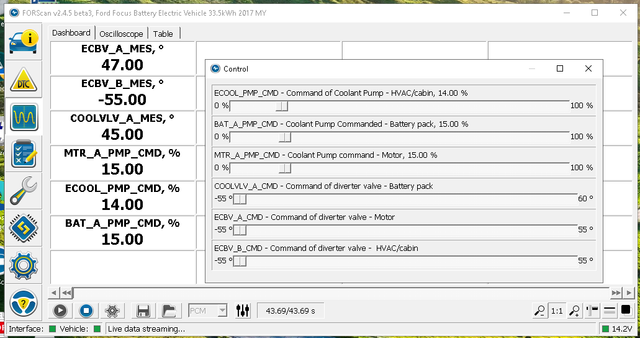

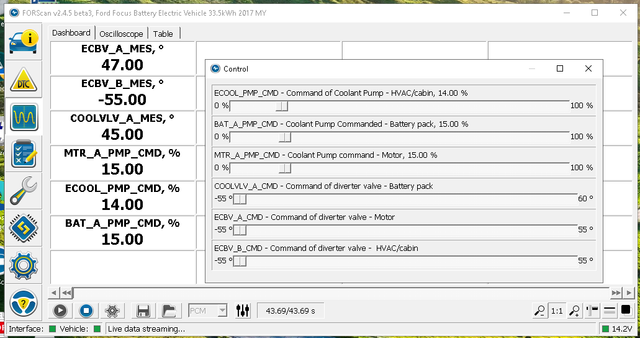

12. Click the Dashboard tab.

13. Click the blue play (right triangle) button at the bottom of the window.

14. Click the greyed out (X'ed out) vertical slider bars button at the bottom of the window.

15. In the control window that opens, set the horizontol sliders for the pump speeds and valve positions. After setting a value, there is a time delay to achieve the setting.

16. The dashboard will show what the actual speeds and positions are in real time.

NOTE: If you set a speed to 100% , you have a high probability of causing air entrapment and enrichment. This is because of the pressure drop across the degas lines will cause them to suck, rather than drain. Similarly if you set a valve all the way one way, with a moderate speed. So with all that in mind, try to set the valves to the 0 degrees (center position), and try to keep the pump speeds less than 75%.

The best way to get air out of the cooling system is to use a vacuum coolant bleeder. Using one of those and setting valves to 0 and pump speeds to 50% does a good enough job.

NOTE: Often the pump speeds will not return back to 0, even though you set the sliders to 0. You will have to power cycle the car to reset them back to normal.